One wouldn’t expect that hydro-excavation (leading to the invention of hydrovacs) was most likely innovated during the California Gold Rush, but it makes sense that miners would want a faster way to cut through the earth to prospect for riches.

Throughout the decades, improvements were made until infrastructure maintenance demanded a more intelligent solution, which led to the first dedicated vacuum excavators being introduced in 1969, by Vactor.

Vactor® is a reputable manufacturer of high-quality vacuum excavation equipment that focuses on vacuum excavators and safe digging. It has led the industry in developing hydrovacs and sewer cleaners with cutting-edge technology and uniquely customizable designs for more than 100 years.

Since then, more than 10,000 Vactor units have been sold globally, surpassing the sales of any other producer of hydrovacs or sewer cleaners. They manufacture a large range of Hydro Excavators, Jetters, Catch Basin Cleaners, and Combination Sewer Cleaners. Rest assured that every Vactor or Truvac product comes with a wealth of design experience in their respective industries.

Determined to go a step further, Vactor developed the TRUVAC brand to support safe digging for municipalities and contractors. The increasing demand for efficient, reliable, and safe excavation methods in construction and utility sectors is prominent – from now to 2031, the hydro excavation truck market is expected to increase at a pace of 11.2% per year worldwide.

Looking at TRUVAC and Vactor Equipment Applications

Vactor has established the benchmark for superiority in operator-focused innovation for over a century. It has been producing high-pressure water and vacuum equipment for 50 years, with more than 55 years of experience building specialized vacuum excavators.

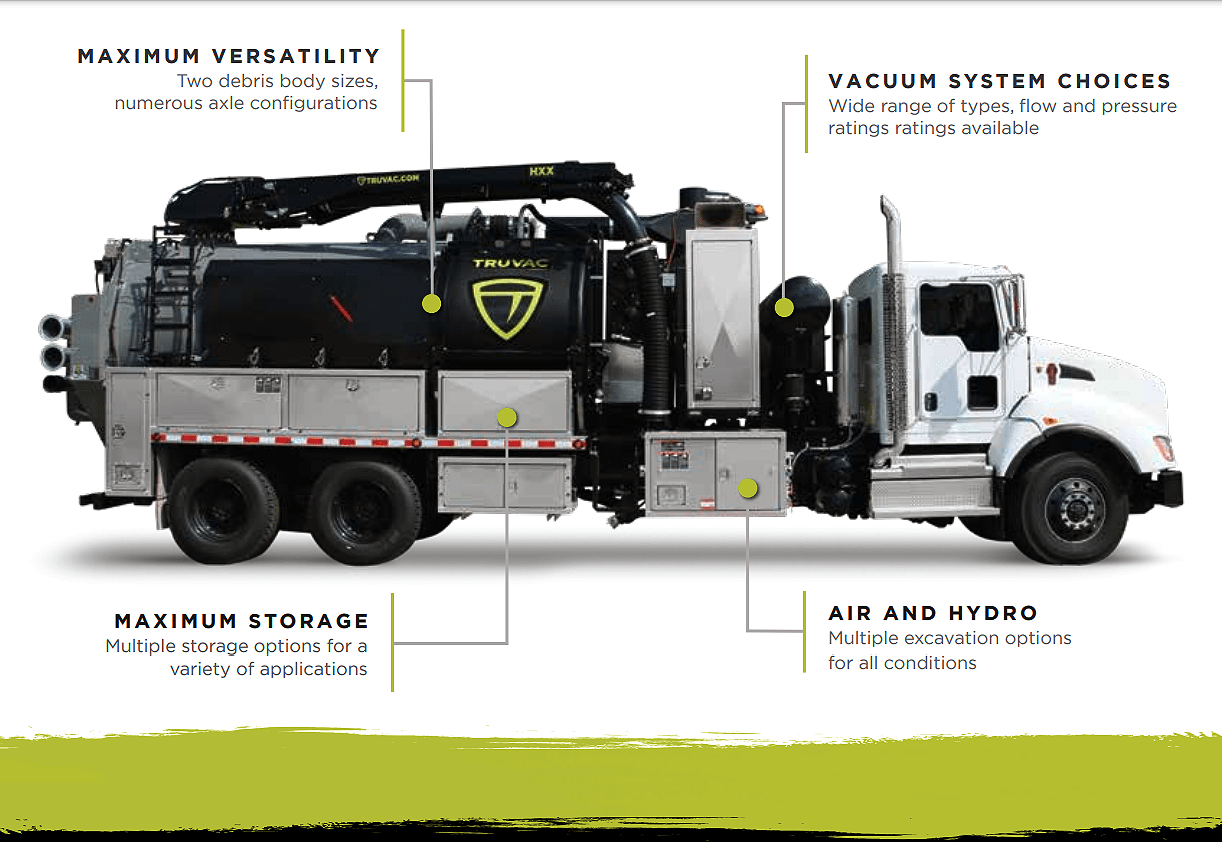

Every TRUVAC vacuum excavator is designed with a commitment to quality and innovation. They are is considered across the industry as the hardest-working, best-engineered equipment available.

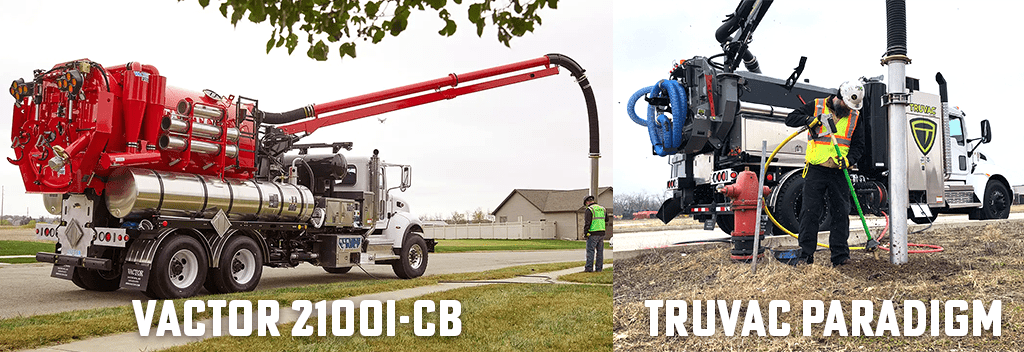

TRUVAC vs Vactor – What’s the Difference?

While the Vactor brand will continue to concentrate on equipment solutions for cleaning and maintaining catch basins and sewers, the TRUVAC brand focuses exclusively on vacuum excavation equipment.

TRUVAC: Smart Solutions for Non-Destructive Excavation

Safely locating and excavating around delicate underground utilities is a common challenge for excavation projects. TRUVAC is the go-to choice for projects that require careful handling of underground infrastructures, such as gas lines, water mains, and fiber optics.

Beyond just safety, TRUVAC is also known for minimizing environmental impact. Precision excavation technology is used for precision and minimal disruption to surrounding areas, plus enhanced safety that vacuum excavation offers for “daylighting” – the process of digging to expose and visually confirm the location of underground utilities, also known as “safe digging.”

To keep things safer, vacuum excavation utilizes either pressurized air or water along with an industrial-strength vacuum to excavate and evacuate soil spoils simultaneously. This minimally invasive technique allows for rapid exposure of underground utilities while minimizing damage, and is particularly beneficial in borehole and trenching applications.

Achieving Excavation Precision in Challenging Locations

Certain environments, such as urban and residential areas or landscaped grounds, demand more precise and safer alternatives to traditional mechanical or shovel digging. The midsize TRUVAC® FLXX™ vacuum excavator is engineered for a wide range of applications where reducing site damage is critical.

This includes urban settings, residential yards or mature plantings with extensive root systems. Work with our experts to determine the right size and configuration of equipment for YOUR application. We strive to provide Utilities, Contractors & Municipalities with increased usable legal payload capacity, maximized job productivity.

Notable features summary:

- Precision Excavation Technology: TRUVAC’s systems ensure accurate and efficient digging and reduce the risk of damaging underground utilities.

- Patented Remote Hose Handling: This technology enhances operator safety and operational efficiency, allowing for precise control over-excavation.

- Advanced Safety Features: From ergonomic designs to automated safety systems, TRUVAC prioritizes operator well-being and site safety.

VACTOR: Innovation in Sewer Cleaning Equipment

Vactor offers a broader array of applications beyond hydro-excavation. Vactor equipment is renowned for sewer cleaning, catch basin cleaning, and jetting. The versatility of Vactor machines makes them indispensable for municipalities and contractors who need multifunctional equipment to handle various tasks efficiently.

The sewer maintenance and sanitation sector has witnessed many changes, particularly with the development of advanced equipment. Vactor proudly leads the innovation with sewer cleaning equipment like the Vactor 2100i and the Vactor iMPACT that showcase cutting-edge technology and robust capabilities.

Vactor 2100i

The Vactor 2100i is a perfect example of Vactor’s dedication to innovation and functionality. Prioritizing the operator, it features advanced technology designed to enhance performance and ease of use. Its intuitive, one-touch in-cab controls for PTO/Transfer Case activation elevate safety and efficiency on the job site. Vactor also designed every piece of equipment with a few guiding principles: Simplicity of operation, safety, ergonomics, effiency of operation and low noise and carbon emmissions.

Vactor 2100i’s Jet Rodder Water Pump, known for smooth, continuous flows and minimal maintenance, offers an optional “jackhammer” action for tough jobs. With a high-strength aluminum water tank for maximum capacity, lower RPM for better fuel economy, and over 100 customizable enhancements. Vactor 2100i sets the standard for sewer cleaning equipment.

Vactor iMPACT

Vactor iMPACT combines top-tier technology in a compact, budget-friendly design, proving that performance does not need to be sacrificed for cost-effectiveness. Sharing the IntuiTouch controls of the 2100i, the iMPACT allows simple PTO activation at the touch of a button and integrates all cleaning system functions into a single, user-friendly interface.

Everything about the design strives to enhance safety and efficiency in multiple situations, from tight alleys to emergency scenarios. Vactor iMPACT is equipped with a low-maintenance Jet Rodder Water Pump, a powerful Positive Displacement Vacuum Blower, and a high-strength aluminum water tank. It demonstrates that smaller equipment can still deliver powerful performance, with customization options to suit various needs.

Notable features summary:

- Versatility: Vactor offers a wide range of vacuum excavation equipment products and sewer cleaners, tailored to meet diverse municipal needs.

- Robust Engineering: the equipment is built to withstand heavy-duty operations, ensuring longevity and reliability.

- User-Friendly: Vactor equipment prioritizes ease of use, with intuitive controls and maintenance features that enhance productivity.

When looking to choose the right equipment, it is important to understand the difference between suction excavation, dry vacs, and hydrovac trucks.

Hydrovac vs Dry Vac Trucks

Project managers are familiar with excavation methods like hydrovac excavation and dry suction excavation. Although they may seem similar, subtle differences distinguish these essential techniques. Understanding these variations is crucial for effective utilization of vacuum excavation equipment. Work with our team to help determine the best choice(s) for your applications.

Hydrovac Trucks

Hydrovac technology uses high-pressure water to loosen soil and a powerful vacuum to remove the slurry. This method is ideal for precision work in wet conditions and areas where underground utilities are present. When dealing with softer soils or when non-destructive digging is required, hydrovac trucks are the better option.

Dry Vac Trucks

Dry Vac technology, conversely, relies on air instead of water. These trucks are perfect for dry conditions and bulk material removal, such as sand, gravel, and dry dirt. Suction excavation is globally recognized as the safest method for digging around underground utilities. Dry vac trucks also excel in scenarios where water use is restricted or where the excavated material needs to be reused or transported without added moisture.

When to Hydrovac vs Dry Vac

Having trouble deciding between Hydrovac and Dry Vac? The decision depends on many factors. Each type of equipment is more suitable for the following conditions:

|

Hydrovac |

|

Dry Vac |

|

● wet, soft soils |

Site Conditions |

● dry, loose materials |

|

● slurry |

Materials |

● reusable dry materials |

|

● minimal disturbance |

Environment |

● areas with water restrictions |

|

● best for precision work |

Application |

● best for bulk material removal |

Partner With an Experienced and Reliable Provider

Joe Johnson Equipment (JJE) is the number one source for Municipal and Contractor equipment. In addition to new and used Refuse & Recycling Collection Vehicles, JJE also sells, rents, leases, and provides maintenance for industrial vacuums, street sweepers, sewer equipment, vacuum excavation equipment, snow equipment, ice makers, sewer nozzles, vacuum systems, and mowers.

Factory-trained and licensed technicians at JJE can offer Preventative Maintenance Programs, Parts & Services, and Product Support. Plus, access to fully furnished, round-the-clock service facilities located in both Canada and the US.

Explore the full range of TRUVAC and Vactor products available and let us ensure you get the best equipment for the job.